Showing 13–24 of 31 results

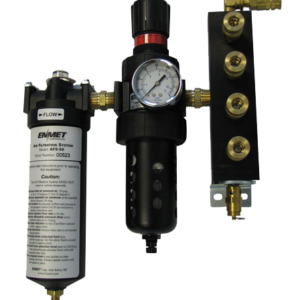

AFS-100

AFS-100 is a compact compressed breathing air filtration system that removes oil, water, solid particles and odors from a compressed air system. AFS-100 system incorporates a unique three-stage filtration concept which utilizes a prefilter, high-efficiency coalescer filter and charcoal adsorber element. The system provides uniform air distribution to five supplied-air respirators and a sixth quick-disconnect can be used for connecting a carbon monoxide monitor or an additional respirator. AFS-100 is compatible with a variety of ENMET carbon monoxide and oxygen monitors.

AFS-50

AFS-50 is a compact compressed breathing air filtration system that removes oil, water, solid particles and odors from a compressed air system. AFS-50 system incorporates a unique three-stage filtration concept which utilizes a prefilter, high-efficiency coalescer filter and charcoal adsorber element. The system provides uniform air distribution to four supplied-air respirators and a fifth quick-disconnect can be used for connecting a carbon monoxide monitor or an additional respirator. AFS-50 is compatible with a variety of ENMET carbon monoxide and oxygen monitors.

AirGuard

AirGuard™ is a next-generation portable breathing air system which meets NFPA and OSHA Grade D breathing air requirements. It has a large external digital color display and audio alarm, and a data logger for OSHA compliance recordkeeping. It integrates a three-stage filter system with Carbon Monoxide, differential Dew Point and CFM flow sensors.

AirGuard™ is available in a variety of CFM capacities, with multi-port line connections and fitting types allowing ease of compatibility with breathing air accessories. AirGuard™ regulates, purifies and monitors supplied breathing air for both safety and comfort.

CO Guard

CO-GUARD is a compact, easy to install and operate compressed airline carbon monoxide monitor that meets OSHA monitoring requirements for Grade D breathing air. The instrument is specifically designed for trouble-free operation, utilizing an electrochemical carbon monoxide (CO) sensor with a life expectancy of up to three years. The CO-GUARD is supplied with a regulator assembly and five foot sample hose, and is factory pre-calibrated.

CO-GUARD is designed for use in a wide variety of applications ranging from automotive paint spray operations to wood finishing. This monitor can be used in virtually any commercial or industrial process that requires carbon monoxide monitoring of compressed breathing air for personnel working in such operations.

DF Series

The filter design combines high performance, greater efficiency, ease of use, flexibility and safety.

- High performance — the flow-optimized filter design, paired with innovative filtration technology, reduces pressure loss by 50% compared to conventional filters.

- Safety — the unique bayonet lock ensures that the filter cannot be opened under pressure for increased safety.

- Energy savings — you will find that greater energy savings are achieved through timely filter element replacement. Element change out is determined by the Economizer that continuously measures the differential pressure. An integrated microprocessor evaluates the measured data and compares the higher energy costs caused by pressure loss with the costs of a new filter element.

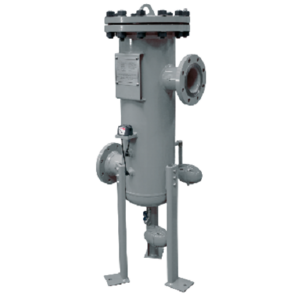

ELM Series

GON Series

MBL Series

Mikropor MBL Series Blower Purge Heated Desiccant Air Dryers provide constant -40 °F pressure dew point with No Purge Air Losses.

These energy efficient dryers are designed to supply clean and very dry compressed air for critical applications.

Pre-filters and after-filters are standard offerings on all Mikropor Blower Purge Air Dryers to keep the air stream clean and maintain the integrity of the desiccant medium.

A centrifugal blower and high efficiency heater eliminates the use of valuable compressed air to be used for desiccant regeneration.

The completely automatic drying system uses blower to pull ambient Air and pass it through the heater. This hot Air stream flows opposite to drying flow direction. Hot Air above 392°F regenerates the moisture inside desiccant bed and strips it completely of all moisture.

The advanced control system monitors the dew point and adjusts the heating / regeneration accordingly thereby providing valuable energy savings.

MCY Series

Advantages

• Best-in-class low package pressure drop saves energy consumption from the supplying air compressor.

• Thermal mass technology offers stable pressure dewpoint at varying loads.

• Mikropor state of the art “3 in 1” cast aluminum heat exchanger provides unmatched longevity & cooling.

• Glycol cooling components are all stainless steel.

• 150 F Max inlet temp design max air flow.

Advanced “3 in 1” Heat Exchanger

Thermally Optimized Encapsulated Design

• Air to Air Exchanger

• Thermal Mass to Air Exchanger

• Multistage Moisture Separation High Strength Aluminium Design Large Surface Area for Heat Transfer Robust Cylindrical Casing

Scroll Refrigerant Compressors:

• Have fewer moving parts

• Offer smoother and quieter operation

• And are more reliable and more efficient than reciprocating types

Digital controller and onboard filters (up to 2750 CFM) are standard

MedAir 2200

MedAir 2200 is a compact, easy to install and operate compressed airline monitor that can continuously and simultaneously monitor up to four gases in real-time using internally mounted sensors. MedAir 2200 is typically configured to monitor hospital compressed air for carbon monoxide, oxygen and dew point. MedAir 2200 is designed to meet OSHA monitoring requirements for Grade D breathing air, NFPA 99 “Medical Air System Guidelines” and is UL and CSA certified for “Medical Electrical Equipment Safety Requirements” (UL/IEC 60601-1 and CSA 22.2, No. 601-1). MedAir 2200 is ENMET’s most advanced compressed airline monitor for medical air systems, specifically designed for hospital applications.

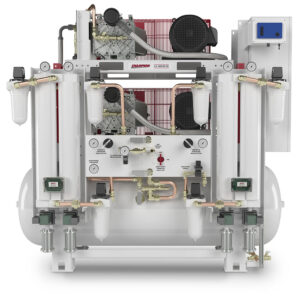

Medical Air Systems

Columbus Compressor offers many options for NFPA compliant medical air systems. We offer consultation, design, and package services custom tailored to your needs. Whether lab, instrument, or medical breathing air, Columbus Compressor can assist you with your next medical project.

Our solutions include:

Scroll, Piston, and Rotary compressor options

Custom built PLC controllers giving you ultimate control and scalability

Consultation, sizing, and design services

Enmet air monitoring equipment and calibration

Dryers, filters, and accessories

Installation services

MHL Series

Mikropor MHL Heatless Desiccant Air Dryers provide constant -40 °F ( -94 °F Optional ) pressure dew point. These dryers are designed to supply clean and very dry compressed air for critical applications. Pre-filters and after-filters are standard on all Mikropor Heatless Air Dryers to keep the air stream clean and maintain the integrity of the desiccant medium.